Technology

Microstructural Refinement of Tool Steel

Tool steels are indispensable materials in various industrial fields, and are used for cutting tools, dies, molds, and so on. Tool steels have been developed through the addition of large amounts of alloying elements in order to disperse many carbide particles in iron based matrix. However, the improvement of mechanical properties, such as hardness, by the compositional modification has become limited. Furthermore, the amount of alloying elements should be reduced because of resources savings, cost reduction, and recyclability requirements.

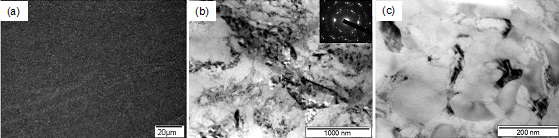

The matrix grains and carbide particles of D2 were significantly refined by "laser hybrid forging". The microstructure and microhardness were evaluated by observations of the grain size and phase of the matrix, and the size and dispersion of the carbide particles. The obtained results can be summarized as follows.

- The nanometer-sized microstructure consists of a fine carbide (particle size: ~100 nm) and matrix (grain size: ~200 nm) as fabricated by laser hybrid forging.

- The carbide is the M7C3 type for the treated D2.

- The microstructural constituent of the treated D2 is martensite and the retained austenite.

- The nanostructured D2 has an extremely high hardness of about 900 HV even with its relatively high amount of retained austenite.

Figure Microstructure of the D2 treated by laser hybrid forging. (a) OM image, (b) TEM image, and (C) enlarged image of (b).